- 您现在的位置:买卖IC网 > Sheet目录1223 > KIT33812ECUEVME (Freescale Semiconductor)KIT DESIGN FOR 33812/S12P

�� �

�

Appendix� B:� Software� Reference� Manual�

�represents,� the� angular� rate� of� rotation� can� be� calculated� and� then� used� to� schedule� the� start� of� an� event�

�in� the� future.� When� the� start� of� the� event� occurs,� the� end� of� the� event� can� be� scheduled� based� on� the�

�current� data� parameters� of� the� fuel� and� spark� controllers.�

�F� u� e� l� C� o� n� t� r� o� l� l� e� r�

�Next� F� uel� Event� Data�

�T� o� o� o� t� h� h� c� c� o� u� u� n� t�

�P� u� l� l� s� s� e� e� w� i� d� d� t� h� h�

�N ext Spark Event D ata�

�T� o� o� o� t� h� h� c� c� o� u� u� n� t�

�D� w� e� l� l� S� t� a� r� t�

�Figure� 26.� Fuel� Controller� Software� Model�

�S� p� a� r� k� C� o� n� t� r� o� l� l� e� r�

�F� u� u� e� l� I� n� n� j� e� c� t� o� r� O� u� t� t� p� u� u� t�

�I� I� g� n� n� i� i� t� i� i� o� n� C� o� i� l� l� O� u� u� t� p� p� u� t�

�S� S� p� a� r� r� k� k� S� t� t� a� r� t� t�

�Figure� 27.� Spark� Controller� Software� Model�

�New� data� related� to� when� the� fuel� and� spark� events� occur� and� for� how� long,� are� determined� by� the� Engine�

�Management� task.� The� basis� of� this� new� data� is� a� table� look� up� using� engine� speed� and� load� data�

�provided� by� the� User� Management� task.� Once� the� table� look� up� takes� place,� any� modifiers� to� the� base�

�table� look� up� can� then� be� added� to� create� a� value� that� can� be� used� by� the� fuel� or� spark� controller.� To�

�prevent� complications� and� undesired� operation,� any� new� data� calculated� by� Engine� Management� will� go�

�into� a� variable� that� will� not� be� loaded� by� the� fuel� or� spark� controller� until� the� current� event� completes.� This�

�lockout� mechanism� prevents� malicious� modification� to� fuel� or� spark� timing� during� a� fuel� or� spark� event.�

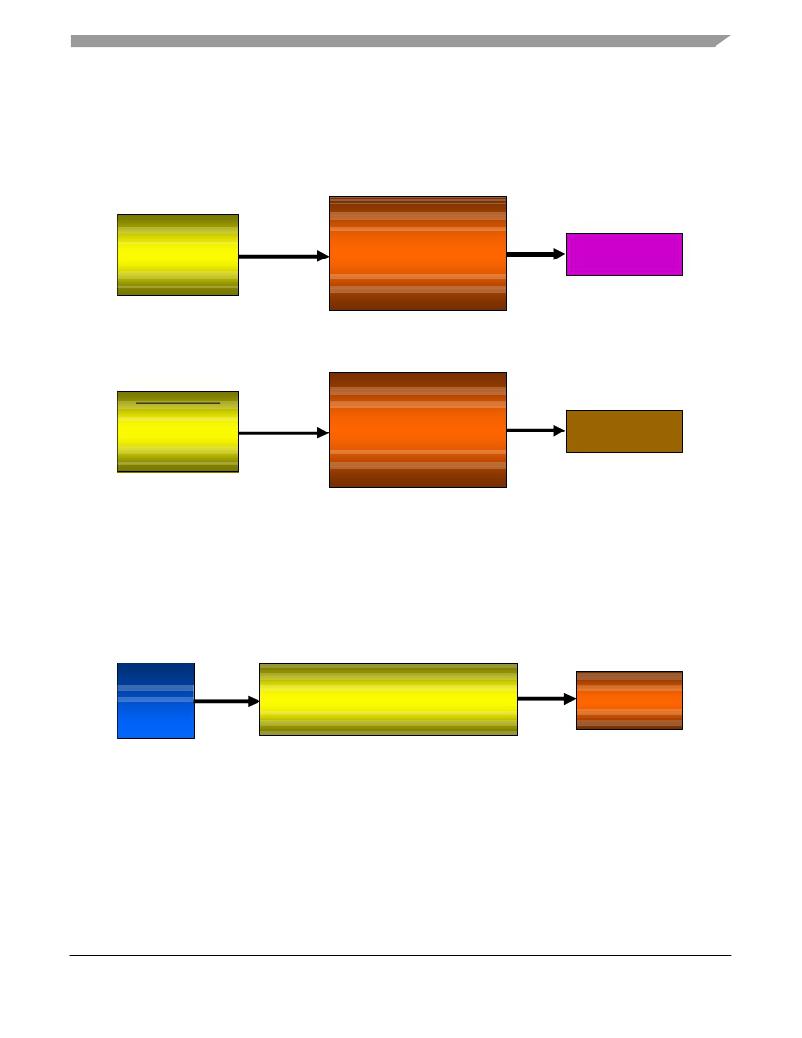

�L� O� A� A� D� D�

�R� P� M�

�A� d� d� e� r� r� v� a� a� l� l� u� e� s�

�B� a� s� s� e� t� a� b� l� e� e� l� l� o� o� k� k� u� p�

�E� n� g� i� n� e� M� a� n� a� g� e� m� e� n� t�

�F� F� i� n� n� a� a� l� l� v� a� a� l� l� u� e�

�c� a� a� l� l� c� u� u� l� l� a� t� i� o� o� n�

�N� N� e� x� x� t� F� u� u� e� e� l� l� a� n� d� S� S� p� p� a� r� k� k�

�E� E� v� e� e� n� n� t� t� S� S� c� h� e� d� d� u� u� l� l� i� n� n� g�

�Figure� 28.� Engine� Management� Software� Model�

�All� data� collection� is� performed� by� the� Data� Management� task,� with� two� exceptions:� engine� speed� and�

�optionally� MAP� data.� As� the� crankshaft� controller� uses� tooth� period� data,� it� makes� sense� for� it� to� collect�

�this� data� for� use.� Measuring� MAP� at� specific� teeth� has� strong� benefits� to� the� system� and� allows� four-cycle�

�synchronization� without� a� cam� sensor.� The� Data� Management� task� is� designed� to� collect� data� at� a�

��Freescale� Semiconductor�

�57�

�发布紧急采购,3分钟左右您将得到回复。

相关PDF资料

KIT33812EKEVBE

BOARD EVALUATION FOR MC33812

KIT33879AEKEVBE

BOARD EVALUATION FOR MC33879

KIT33880DWBEVB

KIT EVAL FOR MC33880 8X SW W/SPI

KIT33886DHEVB

KIT EVAL FOR MC33886 H-BRIDGE

KIT33887EKEVBE

BOARD EVALUATION FOR MC33887

KIT33887PNBEVB

KIT EVAL 33887 5A H-BRIDGE PQFN

KIT33905D5EKEVBE

KIT EVALUATION FOR MC33905

KIT33912EVME

KIT EVALUATION FOR MC33912

相关代理商/技术参数

KIT33812ECUEVME

制造商:Freescale Semiconductor 功能描述:Small Engine Control Reference Design

KIT33812EKEVBE

功能描述:电源管理IC开发工具 INTEGRATED DUAL LOW & HI RoHS:否 制造商:Maxim Integrated 产品:Evaluation Kits 类型:Battery Management 工具用于评估:MAX17710GB 输入电压: 输出电压:1.8 V

KIT33813AEEVBE

功能描述:电源管理IC开发工具 2 Cylinder Small Engine

RoHS:否 制造商:Maxim Integrated 产品:Evaluation Kits 类型:Battery Management 工具用于评估:MAX17710GB 输入电压: 输出电压:1.8 V

KIT33814AEEVBE

功能描述:交换机 IC 开发工具 2 Cylinder Small Engine RoHS:否 制造商:Maxim Integrated 产品:Evaluation Kits 类型:USB Power Switches 工具用于评估:MAX4984E 工作电源电压:2.8 V to 5.5 V

KIT33816AEEVM

功能描述:电源管理IC开发工具 Engine Control Module RoHS:否 制造商:Freescale Semiconductor 产品: 类型: 工具用于评估: 输入电压: 输出电压:

KIT33879AEKEVBE

功能描述:电源管理IC开发工具 CONFIGURABLE OCTAL RoHS:否 制造商:Maxim Integrated 产品:Evaluation Kits 类型:Battery Management 工具用于评估:MAX17710GB 输入电压: 输出电压:1.8 V

KIT33880DWBEVB

功能描述:电源管理IC开发工具 33880DWB COSS KIT RoHS:否 制造商:Maxim Integrated 产品:Evaluation Kits 类型:Battery Management 工具用于评估:MAX17710GB 输入电压: 输出电压:1.8 V

KIT33883DWEVB

功能描述:KIT EVAL FOR MC33883 PRE-DRIVER RoHS:否 类别:编程器,开发系统 >> 过时/停产零件编号 系列:- 标准包装:1 系列:- 传感器类型:CMOS 成像,彩色(RGB) 传感范围:WVGA 接口:I²C 灵敏度:60 fps 电源电压:5.7 V ~ 6.3 V 嵌入式:否 已供物品:成像器板 已用 IC / 零件:KAC-00401 相关产品:4H2099-ND - SENSOR IMAGE WVGA COLOR 48-PQFP4H2094-ND - SENSOR IMAGE WVGA MONO 48-PQFP